A variety of prototypes had been produced as part of the X-RAY TAG development process. Some of these had been analyzed both with a high-resolution X-ray scanner at a materials research lab, and with X-ray scanners at airports.

Here are some of the examples from the early development process that demostrate that the principle of X-RAY TAGs working quite well.

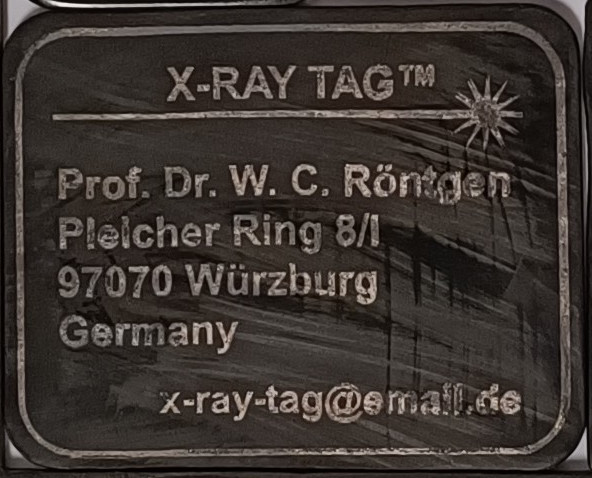

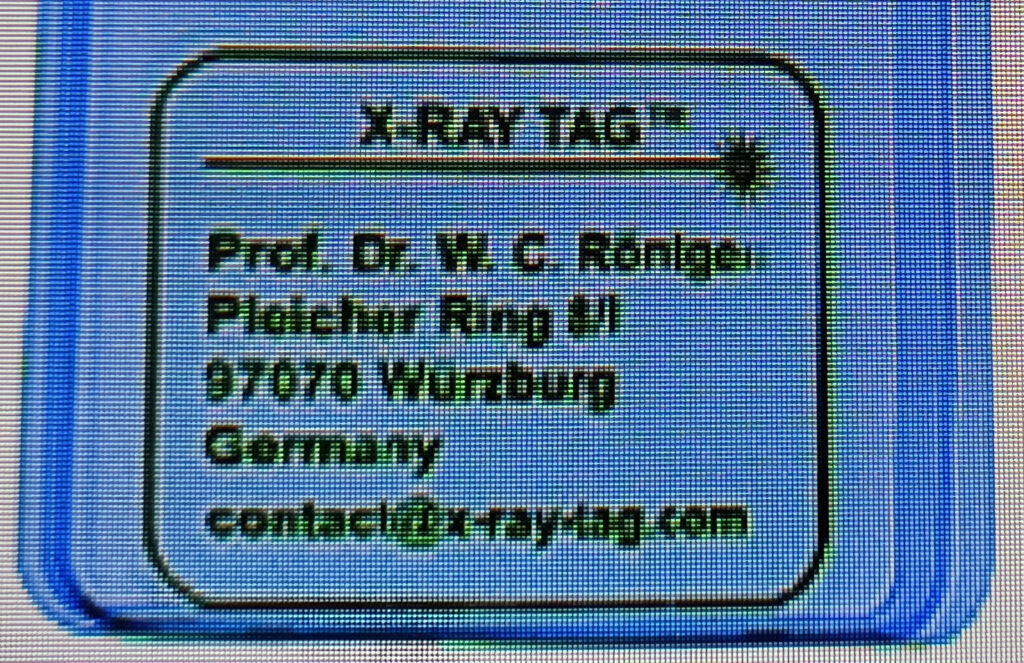

Below a recent prototype of an address type X-RAY TAG, with the name, address, contact details and a logo.

Left: the tag itself.

Right: Scan of the X-RAY TAG with a airport luggage scanner (Smiths Detection system @ ZRH). The tag was packed in a square tin can, hence the blue background.

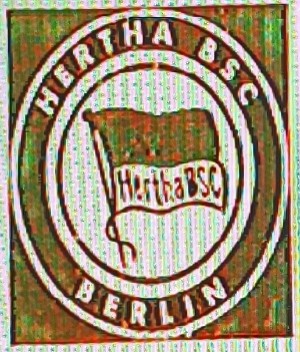

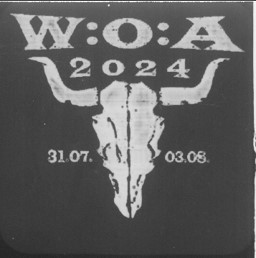

The logos shown below were used for development purposes because they presented certain technical challenges, e.g., for graphics, font, size.

There was no commercial use of the logos. The plates (right) were scanned with with a high-resolution X-ray scanner at 140 keV and with a luggage scanner at an airport, where photos were taken of the computer screens.

Logo Herta BSC, 8 x 8 cm

Logo Wacken Open Air (WOA) 2024, 8 x 8 cm

These early tests indicated that:

The lower effective resolution of the baggage scanners requires a minimum size of the characters, and therefore also of the X-RAY TAGs, to ensure that text is still clearly legible on an inspector’s display.

Graphic elements such as logos can also be reproduced quite well and in good detail with our manufacturing process, but they to have a minimum size to be seen in luggage scans, as very fine lines and details may not be resolved by luggage scanners.